The use of electronics in different fields (e.g. in industry and in the automotive sector) under in part extreme weather requires a high degree of reliability of the electronics components employed. In many cases this reliability can be achieved only with the use of suitable protective materials. With its Bectron® product series, ELANTAS Europe offers a variety of possibilities, based on different chemistries and hardening mechanisms for nearly every application.

In practice, we have often found that electronic protection has been neglected, forgotten or even intentionally suppressed during the development of high-quality components. The avoidance of additional process steps, a greater investment in time, and the resulting additional costs can be decisive here. However, a single recall action due to electronics failures in the field, caused by inadequate electronic protection, can eliminate the previous savings in production costs. The reason for the disapproval of protective materials in the electronics industry may be the conviction that this is “too complicated” or “that doesn’t hold up anyway”.

The reasons for and influences relating to the insufficient effectiveness of a protective material are many and often only recognised in a very advanced stage of the development/project phase. Possible influencing factors are, for example, soiling of the printed circuit board or solder resist residues. Changing the components on the printed circuit board or changing to a new printed circuit board supplier can lead to the worsening of or even hinder the adhesion of the protective materials on the printed circuit board.

Depending on the type and extent of PCB contamination and the corrective measures (e.g. plasma pre-treatment) already in place, in some cases only cleaning the printed circuit board can help. Each corrective action must be performed before a protective material is applied to the printed circuit board.

If a cleaning process is applied, it is essential that all cleaning material residues are thoroughly removed from the printed circuit board prior coating. Otherwise it would impede the coating process. Fundamentally, it must be emphasised that a clean surface free of grease is a prerequisite for the good adhesion of protective materials on the surface of a substrate.

Printed circuit boards are either cleaned by a service provider or this process is integrated in-house via a cleaning plant. Here, the individual case should always be viewed in relation to the project and a decision made according to the particular circumstances. Cleaning processes are well-established, but not always necessary.

In the ideal case, consult ELANTAS Europe at the earliest possible stage in your project phase, so that we can develop the best possible and most effective process together with you.

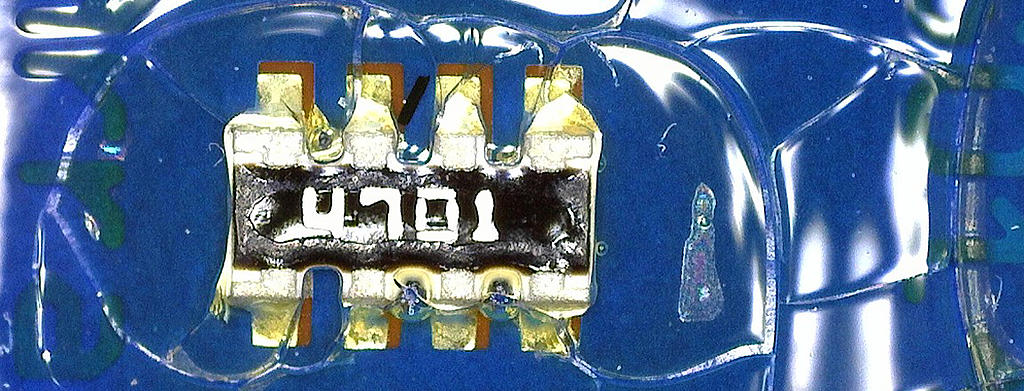

Tabelle 1: Examples for electronic protection

| Type | System | Curing | Example |

| Thin Film Coating | Urethane/Acrylate | UV- / Moisture Cure | Bectron® PT 4700 N |

| Silicone | Moisture / Varnish | Bectron® SDC 76V1-18 | |

| Thick Film Coating | Urethane/Acrylate | UV- / Thermal Cure | Bectron® PL 5622-250 |

| Polyolefine | Melting Resin | Bectron® MR 3405 H | |

| Potting | Polybutatdiene | 2-Component-Reaction | Bectron® PB 3251 |

| Polyurethane | 2-Component-Reaction | Bectron® PU 4537 |

If you have any questions about material selection or specific applications, please do not hesitate to contact us directly at bectron.ELANTAS.europe@altana.com